Pinovo delivers dust-free vacuum blasting solutions

Quick information

- Available

At a glance

Pinovo develops closed-loop surface preparation equipment that reduces waste and pollutants from abrasive blasting. The equipment is certified for offshore use.

Challenge

Surface preparation is the removal of paint and corrosion from steel surfaces through abrasive blasting. It is essential for protecting surfaces from oxidation and increasing their lifetime.

Abrasive blasting, however, pollutes the environment and can damage sensitive equipment nearby by releasing blast media, rust, heavy metals and microplastics.

Solution

Environmentally sound abrasive blasting

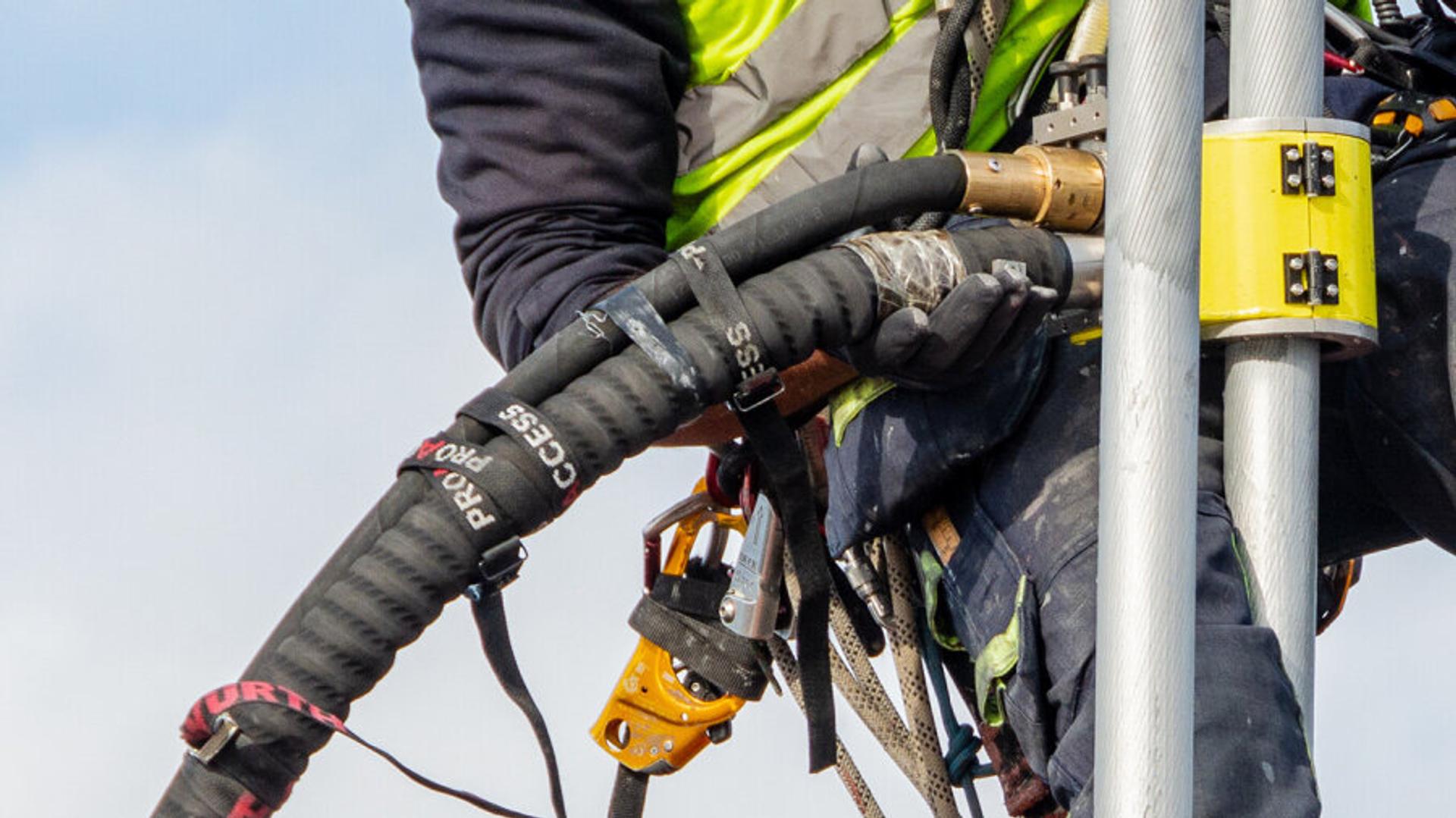

Pinovo has developed an abrasive blasting solution that ensures zero pollution and zero damage. The closed-loop system contains the waste, making Pinovo dust-free, and enables complete waste management control from nozzle to landfill.

Dust-free removal of paint and corrosion protects sensitive equipment such as sensors, turbines and valves from being damaged by grit and dust. In addition, it improves health and safety in the workplace.

Benefits

Pinovo can help to cut surface preparation costs by up to 60 per cent by reducing the need for scaffolding and sheeting, as well as by eliminating clean-up.

The closed-loop system helps to reduce waste with as much as 75 per cent, protecting both the environment, workers, and sensitive equipment from hazardous pollutants.

Market potential

Pinovo is ATEX certified for use in the oil and gas industry, and is currently used on offshore rigs, FPSOs and navy vessels and at onshore petrochemical plants and nuclear power plants.

The offshore rigs in the North Sea, Gulf of Mexico and Persian Gulf represent a combined market potential for Pinovo of over USD 24 million a year.

There is also sizeable market potential in industries with assets made of steel, such as petrochemical plants, wind farms, and naval and commercial shipping fleets.

Pinovo has offices in Norway and the UK, with distributors in the Benelux countries, Canada, France, Trinidad and the US.