What happens when traditional fishing methods meet green technology?

Kjell Gunnar Hoddevik has been captain of a longliner since 1993. When the opportunity to design and build his own, brand-new boat came up, he grabbed it. Innovative technology will make the new longliner safer and more climate-friendly.

“We wanted to be innovative and in the driving seat. We had to improve ourselves to tackle the challenges we see arising in the future,” says the captain.

In 1997, he and his partner Jonny Årvik became shareholders in an established shipping company. Both started out as fisherman – now they own and pilot their own boat.

“The past few years have been good for fisheries in Norway, but we have struggled for a long time,” says Hoddevik.

There are 23 Norwegian fishing boats that use autolining – a mechanised process for longline fishing. These boats catch cod and haddock, which are frozen shortly after being hauled on board and are then sold frozen on the market.

Automated factory on board

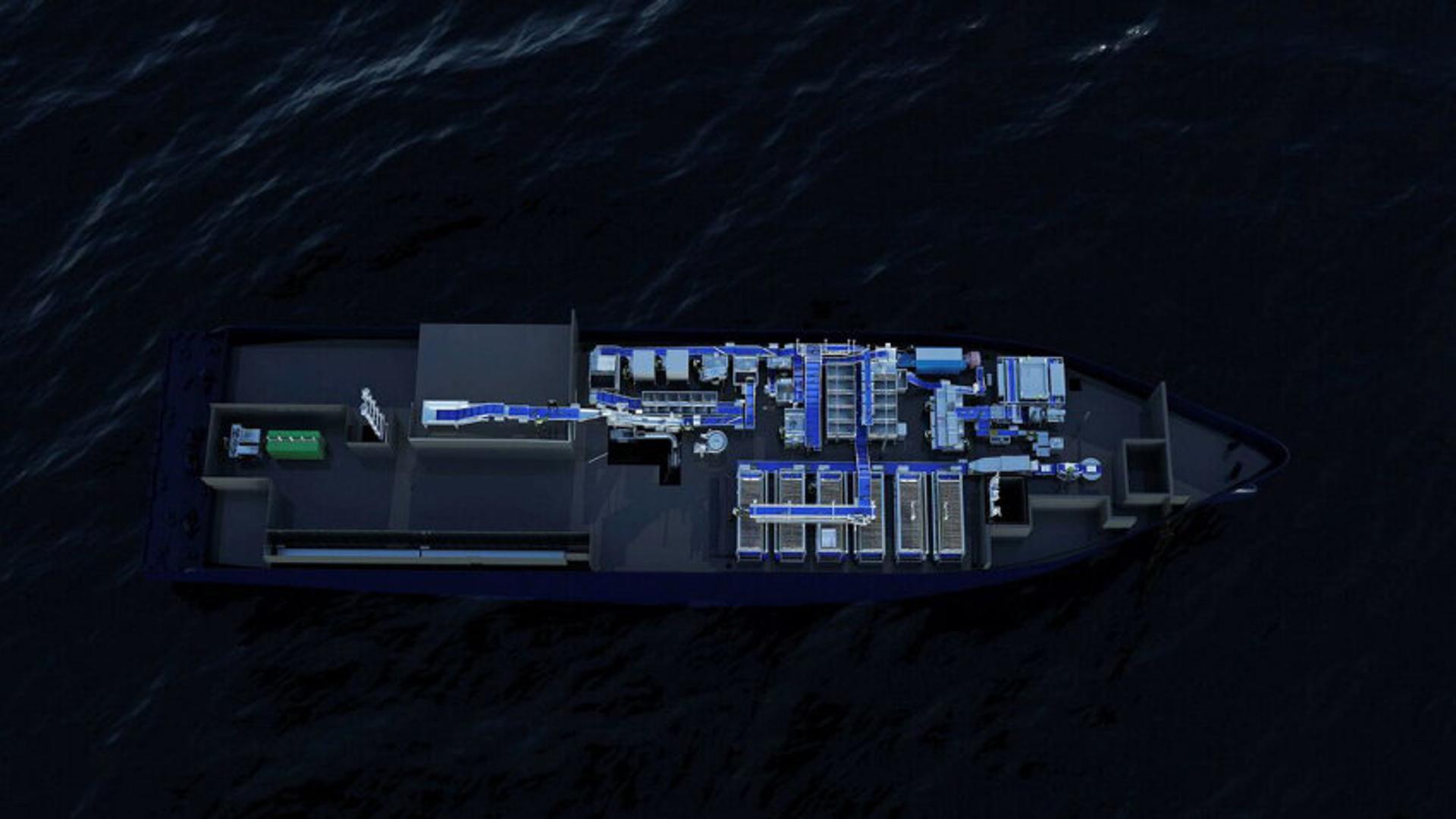

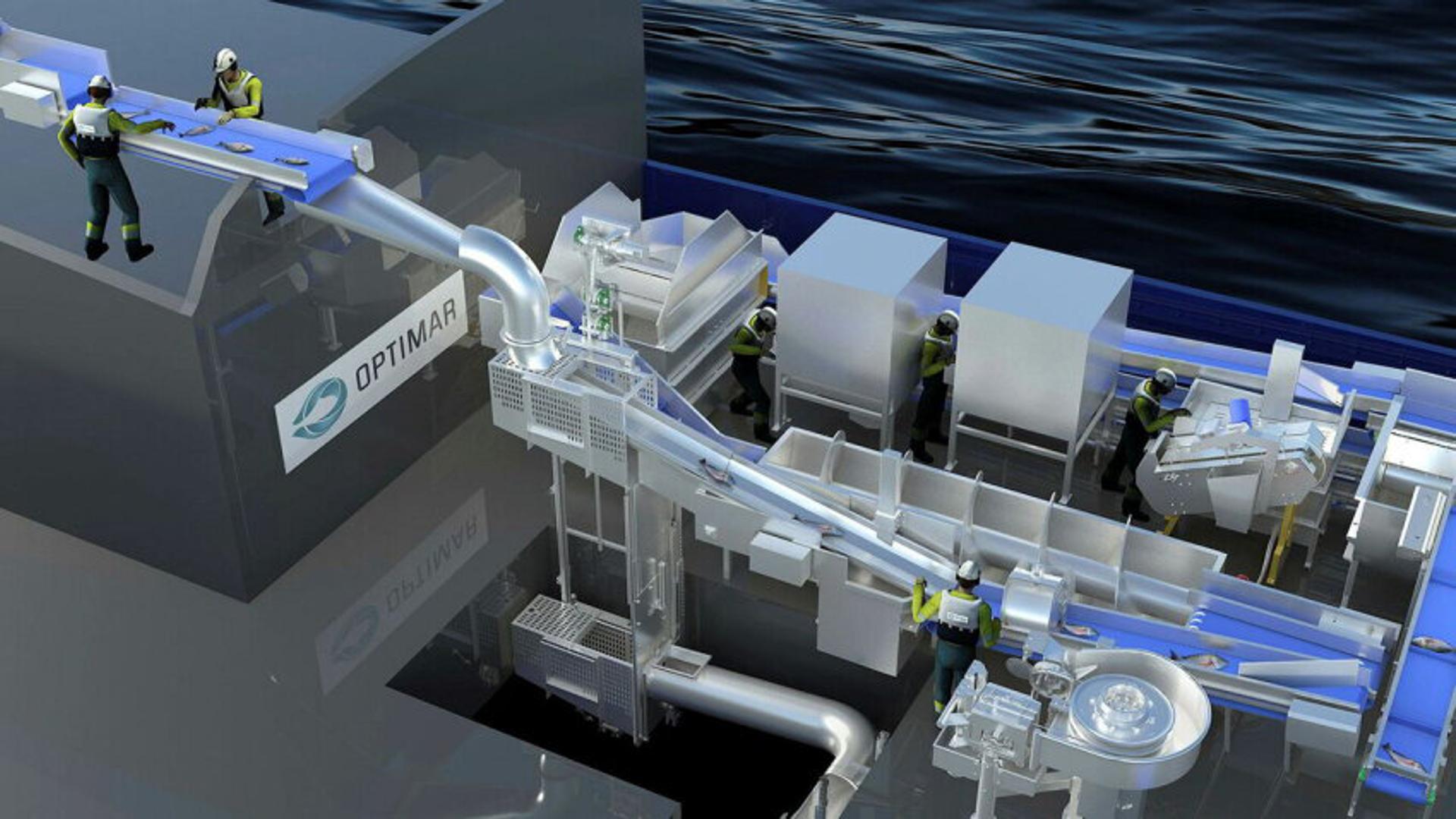

The Atlantic – a 64-m longliner – has been designed by Norwegian ship design consultants Skipsteknisk in Ålesund. It is chock-full of novel solutions.

The onboard factory is nearly entirely automated, from the time the live fish are caught on the line until they are cleaned and stacked frozen on pallets. The fish can also be filleted on their way to the freezer, if desired.

Once a fish is caught, it is anaesthetised before being cut and bled by hand. It is then sorted, weighed, headed, cleaned, packed and processed by machine.

More and more consumers are demanding that the food they eat comes from sustainable sources. Atlantic Longline is fully aware of this. Each segment of the process on board the 20-year-old longliner it operates is environmentally certified and frequently inspected.

“This is important to us. We want to handle the fish gently and properly. They are, after all, living creatures,” says Hoddevik.

Sustainability in practice

The new boat features diesel-battery electric hybrid propulsion. A longliner cannot run solely on today’s batteries. While an offshore vessel or coastal fishing boat is at sea for 24 hours, longliners are at sea for a month at a time. When the propeller is in motion on the Atlantic it will also generate new energy, which can be used for lighting or heating on board.

“Not everyone agrees that this is a smart investment at this time, given the rapid developments in battery technology. Nevertheless, with financing from Enova, we decided to go ahead with this solution, which cuts fuel consumption and associated emissions,” says Hoddevik.

There is a tremendous difference between a new boat and an old boat. Nevertheless, older vessels can be upgraded. Not only can fish processing be modernised and automated, the vessel’s environmental footprint can also be reduced.

“The boat we have in operation has been upgraded continually, but it is not possible to make it as modern as the new one. However, earlier in the year we replaced all the machinery and installed an NOx cleaning system. This has reduced emissions from 54 kg to 6.5 kg per metric ton of fuel.”

Atlantic Longline is also actively collaborating on developing more environment-friendly bait, as the principal shareholder in the Norwegian company Ecobait. Every single hook on the *Atlantic’s *8 000-metre line is baited. The aim is to develop high-quality bait from raw materials that are less resource-intensive than current alternatives.

The use of residual raw materials from fish is also an issue of sustainability. In the new boat, all cuttings from filet production will be frozen for sale to other companies that can create new products on shore.

Exciting design

According to designer Kjetil Nyvoll at Skipsteknisk, it was extremely satisfying to design a local boat packed with innovative solutions – which was sure to draw national and international attention.

“Our job as designers is to sew together an entire boat into a package the shipowners want. There are many features on this boat that were by no means daily fare for a fishing boat four or five years ago. It is very exciting,” he says.

The hull of the Atlantic is planned launched in April 2020, and the vessel will be completed in October.

The original version of this article was published in Norwegian by DNX.