Norway delivers the best and cleanest raw materials for solar

Published 14 Mar 2023 (updated 29 Oct 2025) · 4 min read

Innovation and installation of eco-friendly solar power is increasing dramatically, and the demand for silicon is growing at a pace.

Norway can help to meet this demand with the cleanest silicon in the world.

The global demand for electricity will double during the next few decades. Things are also happening quickly in the international solar market, both in terms of the pace of innovation and the growth in demand.

In the EU, more than 41 GW was installed in 2022, representing a huge annual growth rate that exceeds 50 per cent from 2021. Norway, meanwhile, saw a skyrocketing annual installation rate of 350 per cent, with 149 MW was connected to the grid.

Another record year for solar power

This is close to 40 per cent of the total capacity installed in Norway and an indicator of the rapid growth of solar power in many markets. 2023 looks set to become yet another record year. And when it comes to manufacturing solar cells, Norwegian silicon is the world’s best material.

“In order to manufacture pure silicon, the process of converting the raw material must be energy efficient, and the power used in the process must be clean. Norway delivers on both these points. Norwegian companies have developed unique manufacturing processes that are very energy efficient. In addition, the electricity we use is generated by hydropower,” says Erik Marstein.

“Norway has long traditions within research and production. Norwegian companies have invested considerable time in developing processes that use less energy,” he says.

The world’s coolest element

Today, you can find silicon almost everywhere. Pure silicon is required for much of the technology you use, including the chips in your smartphone or laptop, the image sensors in your camera, and much more. Soon, it may even be in batteries.

“Silicon has atomic number 14, and is the world’s coolest element. It’s the second most abundant element in the earth’s crust, after oxygen. There are other ways of manufacturing silicon, but the Norwegian method is best, based on several criteria,” says Marstein. The disadvantage of silicon is that it cannot be found in its pure state in nature.

“What is unfortunate is that silicon is tied to oxygen in minerals such as sand, quartz, rock crystal, and amethyst. It needs to be refined before it can be used. In Norway, we have done a good job of developing technology to extract silicon with a purity of 99.99999 per cent or more,” he says.

“Solar power is already a very clean way of generating electricity, but there is potential to make production even more energy efficient and environmentally sound.”

Erik Marstein

Director of the Norwegian Research Centre for Sustainable Solar Cell Technology

Strong innovation in silicon manufacturing

Elsewhere, REC Solar Norway is making solar cell silicon at its factory in Fiskaa, outside Kristiansand, in Southern Norway. Its patented process produces super clean silicon. Moreover, the company has received certification for Environmental Product Declarations (EPDs) for silicon and multicrystalline blocks for use in solar cells.

Another example of the rapid pace of innovation is Dynatec Engineering. Together with IFE, Dynatec has developed a new way of manufacturing silicon for solar cells. It has been proven to grow silicon 40 times faster and with far greater energy efficiency than other methods.

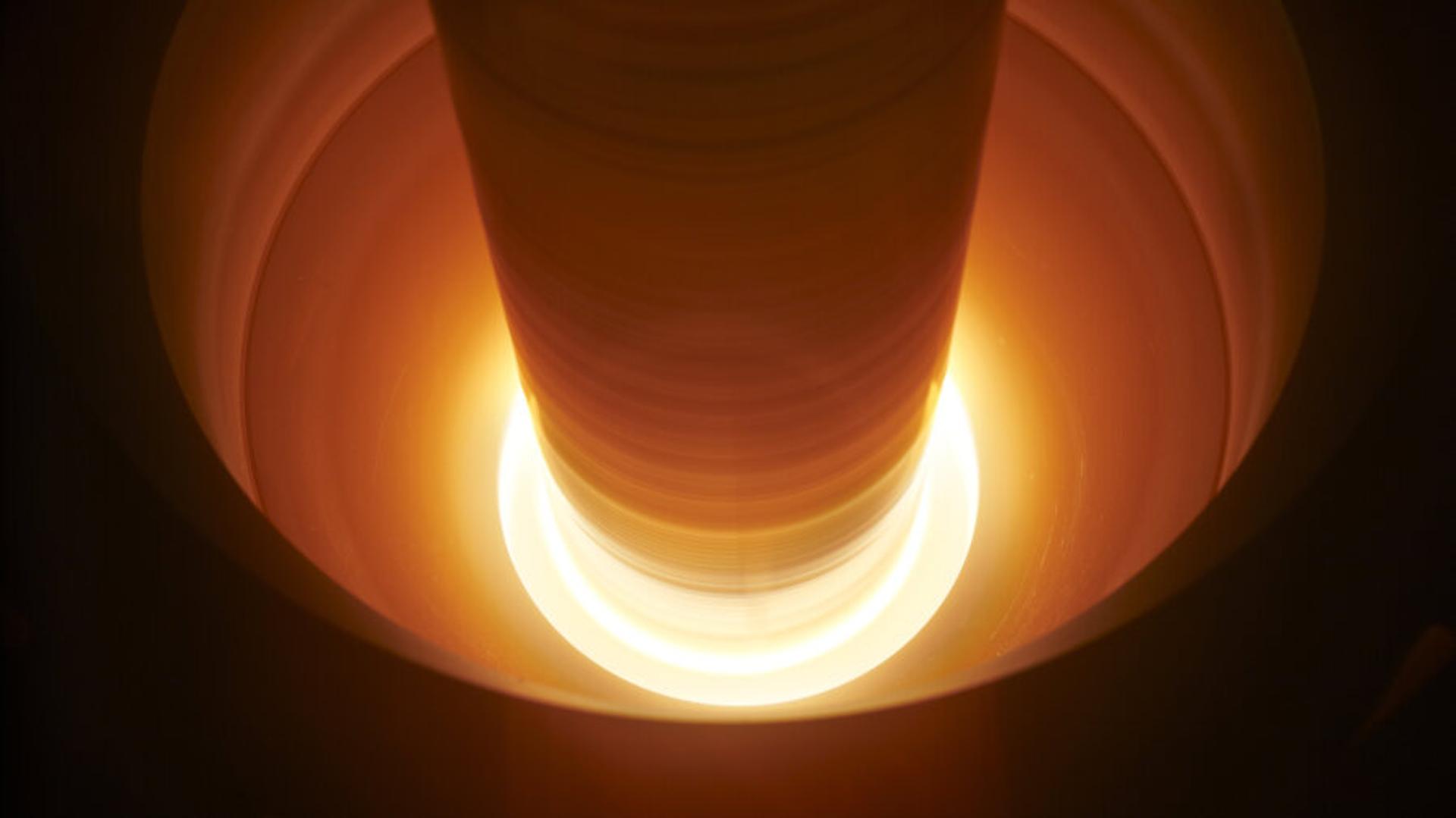

Dynatec’s reactor produces silicon that is almost 100 per cent pure with an ultra-fast, highly energy-efficient method the company has developed. Dynatec received the Innovation Award from the Research Council of Norway for its method.

Better, cleaner, faster and cheaper

Norway is a solar pioneer and has built a large research community. According to Marstein, the solar community functions as an ecosystem in which the various players can draw on synergies.

“Solar power is already a very clean way of generating electricity, but there is potential to make production even more energy efficient and environmentally sound,” he points out.

Although Norwegian companies are likely the world’s best at extracting silicon, they cannot rest on their laurels.

“China in particular but also countries like Japan, South Korea, Germany and the US are major producers of silicon. We must work to stay in the lead. We have to manufacture large quantities quickly and the product needs to be environmentally friendly. It also needs to be cheap. Nobody wants to buy expensive solar cells anymore,” says Marstein.

As long as there is demand for silicon in the solar energy industry, there will be demand for cheaper, purer and better materials. Norwegian companies have their work cut out for them in the years to come.

Every country in the world will need solar cell materials, and we have the chance to gain large market shares,” he points out.

An element for the future

Another market being revolutionised by silicon is battery development. In theory, silicon can increase the capacity of batteries tenfold, which will be very important to the automobile industry, in particular.

“There is an extremely tough global race to develop new types of silicon batteries. Norwegian companies are at the forefront here as well,” says Erik Marstein.

Silicon is definitely a key element for our shared future. Or, as Marstein concludes: “Silicon is essential for the green transition.”

With solar growing by leaps and bounds, the transition is already in full swing for Norwegian solar players. It’s an industry to watch.