Norway perfect for producing green hydrogen with clean hydropower

Published 26 Oct 2023 (updated 29 Oct 2025) · 5 min read

As pressure to curb emissions increases and hydrogen-powered mobility gains momentum, demand for green hydrogen is set to skyrocket.

Norway is playing a leading role in producing the green hydrogen the world needs.

The world is hungry for hydrogen

The world is hungry for hydrogen, with 95 million metric tons produced each year globally to fuel industry. But as many nations begin implementing the terms of the Paris Agreement, hydrogen’s ability to act as an emission-free energy carrier in transportation has demand soaring even further.

Yet nearly 95 per cent of today’s hydrogen supply is grey hydrogen, which is produced through carbon-intensive processes using fossil fuels such as natural gas, methane and coal. The remaining 5 per cent is green hydrogen produced with renewable electricity. Until now, green hydrogen has cost nearly twice as much to produce as grey hydrogen.

However, many predict these costs will be reversed within this decade, as green hydrogen production scales up and the cost of renewable electricity goes down. Norway is at the nexus of this development.

Norway’s rich green hydrogen history

“Norway has a very long history with hydrogen, and Nel has been there from the beginning,” says Thorsten Herbert, Director of Market Development and Public Affairs at Nel, one of the world’s oldest hydrogen companies.

Founded as part of Norsk Hydro in 1927 in Notodden, Norway, the company built the world’s largest water electrolysis plant as early as 1940 in the nearby town of Rjukan, where hydropower from a local dam was used to produce green hydrogen for fertiliser production.

But an abundance of cheap natural gas in the 1950s soon replaced green hydrogen with grey hydrogen, and this remained the case for decades. According to Herbert, this may soon change.

“We are definitely in an interesting period. As carbon taxes continue to climb and the total cost of ownership of green hydrogen declines, the balance is once again turning in favour of green hydrogen,” he says.

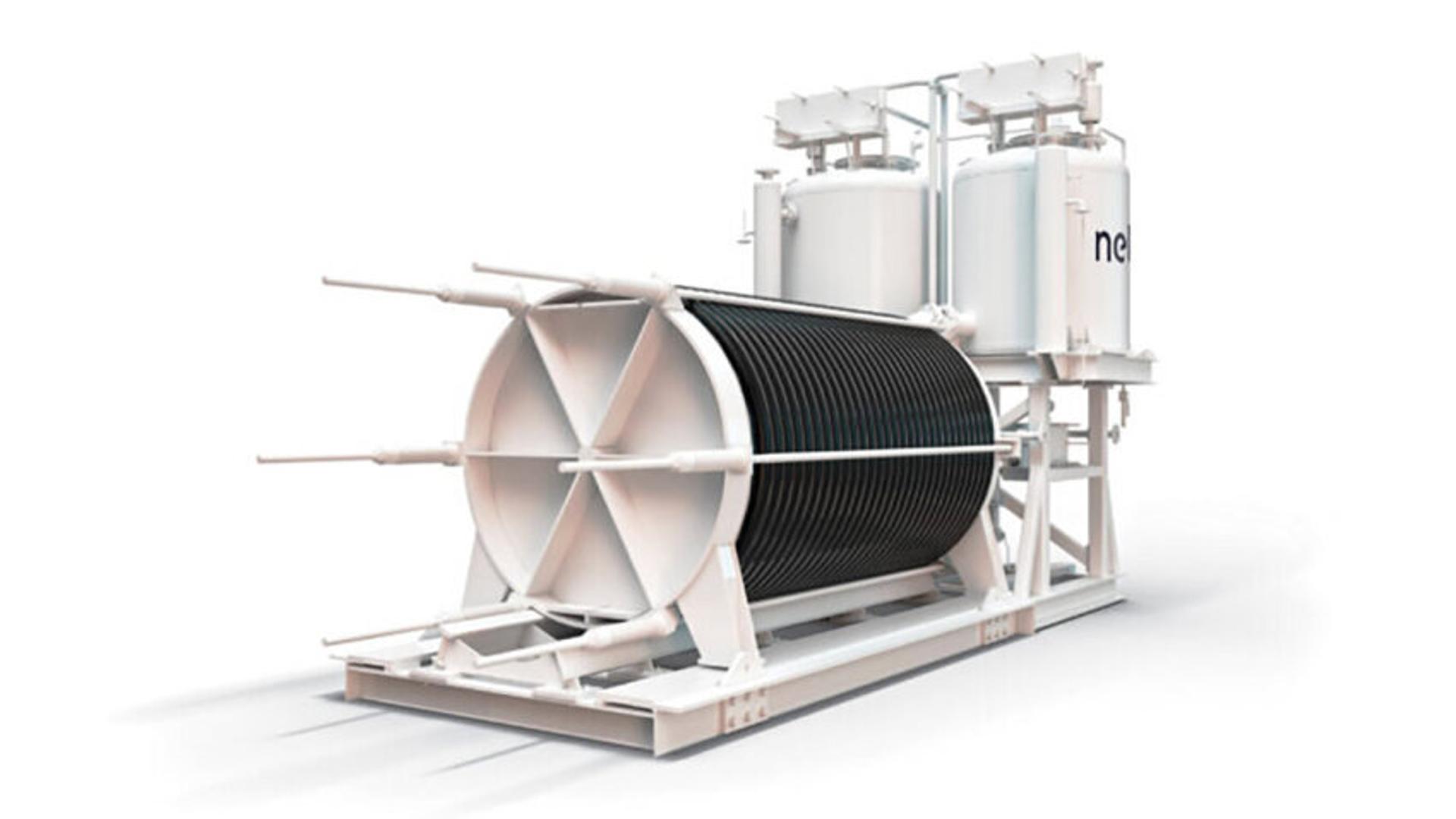

In 2017, Nel’s electrolysers once again made international news when the company announced that it had acquired Proton OnSite, effectively making Nel the largest electrolyser company in the world. It is now utilising its size and expertise to drive down costs.

“Nel is currently constructing a large-scale electrolyser manufacturing plant with a potential capacity of up to 2 GW right here in Norway,” says Herbert.

“Once up and running, the fully automatic plant will produce 10 times Nel’s current annual output, creating the most efficient electrolysers on the market at game-changing costs.”

A new European record in hydrogen

One of Europe’s largest independent research organisations and another hydrogen heavyweight is located in Norway: SINTEF. Headquartered in Trondheim, SINTEF has over 70 years’ experience in applied research and carries out several thousand projects annually for customers of all sizes.

According to Senior Project Manager Anders Ødegård, SINTEF’s hydrogen expertise is increasingly in demand:

“In Norway, there is a major hydrogen push in the maritime sector that we are supporting, including infrastructure projects like the one in the Geirangerfjord, where Norwegian Hydrogen plans to produce and supply hydrogen locally to trucks and ferries, with a project slated to start in late 2023.”

SINTEF’s hydrogen expertise has also earned it a strong position in Europe, with numerous authoritative publications and cutting-edge projects. One such project, Ødegård explains, is about to set a European record.

“SINTEF currently holds a coordinating role in the ongoing construction of the demonstration project REFHYNE, which will be Europe’s largest polymer electrolyte membrane (PEM) hydrogen electrolyser,” he says.

Located in Wesseling, Germany, the REFHYNE facility began production in July 2021. It will eventually reach a capacity of 10 MW and produce up to 1 300 metric tons of clean hydrogen a year.

Building a smart green hydrogen value chain

While the extensive experience of players like Nel and SINTEF is invaluable to creating a functioning green hydrogen economy, a fresh approach can also be helpful.

Founded in 2019 in Horten, Norway, Gen2 Energy is a fast-moving company on a mission to provide Europe with clean green hydrogen.

“When it comes to hydrogen, things are happening very fast. As a young company, we are much more agile and have been able to make decisions quickly in a market that is undergoing rapid change,” says Dr Odd-Arne Lorentsen, CTO at Gen2 Energy.

While some companies set out to solve a single problem, Gen2 Energy is opting for a holistic approach as it aims to develop, build, own and operate an integrated value chain for green hydrogen.

Gen2 Energy is currently scouting locations with optimal production and shipping capacity where electrolysers can be set up to begin production. At its new facility, the hydrogen will be compressed, containerised and transported to consumers as a plug-and-play service. Smart tracking and monitoring will notify users when supply is running low. Once empty, containers are returned to the production site to be refilled.

“What we really bring to the table is that we have thought through the entire value chain,” says Dr Lorentsen.

From drones to power plants

“There’s really no consensus on where the line goes for where green hydrogen can’t be beneficially applied. The range includes everything from tiny drones to megawatt power plants.”

Anders Ødegård

Senior Project Manager, SINTEF

Whatever hydrogen applications may come, established hydrogen actors like Nel and SINTEF are well-positioned to catch the wave. Meanwhile, newcomers like Gen2 Energy are agile enough to quickly navigate the turbulence that is sure to result.

Young or old, the key to success in this growing market hinges on bringing down costs, and all of the companies agree that Norway is the place to do it.

“To make green hydrogen you just need water and zero-emission electricity,” Dr Lorentsen points out.

“There is an unlimited supply of pure water that's essentially free. Electricity in Norway is 100 per cent renewable and remains competitive with prices in Europe,” he concludes.