Battery year in review 2021: Super Bowl ad kicks off winning year for Norway’s battery industry

Norway’s reputation as the EV capital of the world is not just good PR. It is based on genuine progress towards a green, circular battery ecosystem.

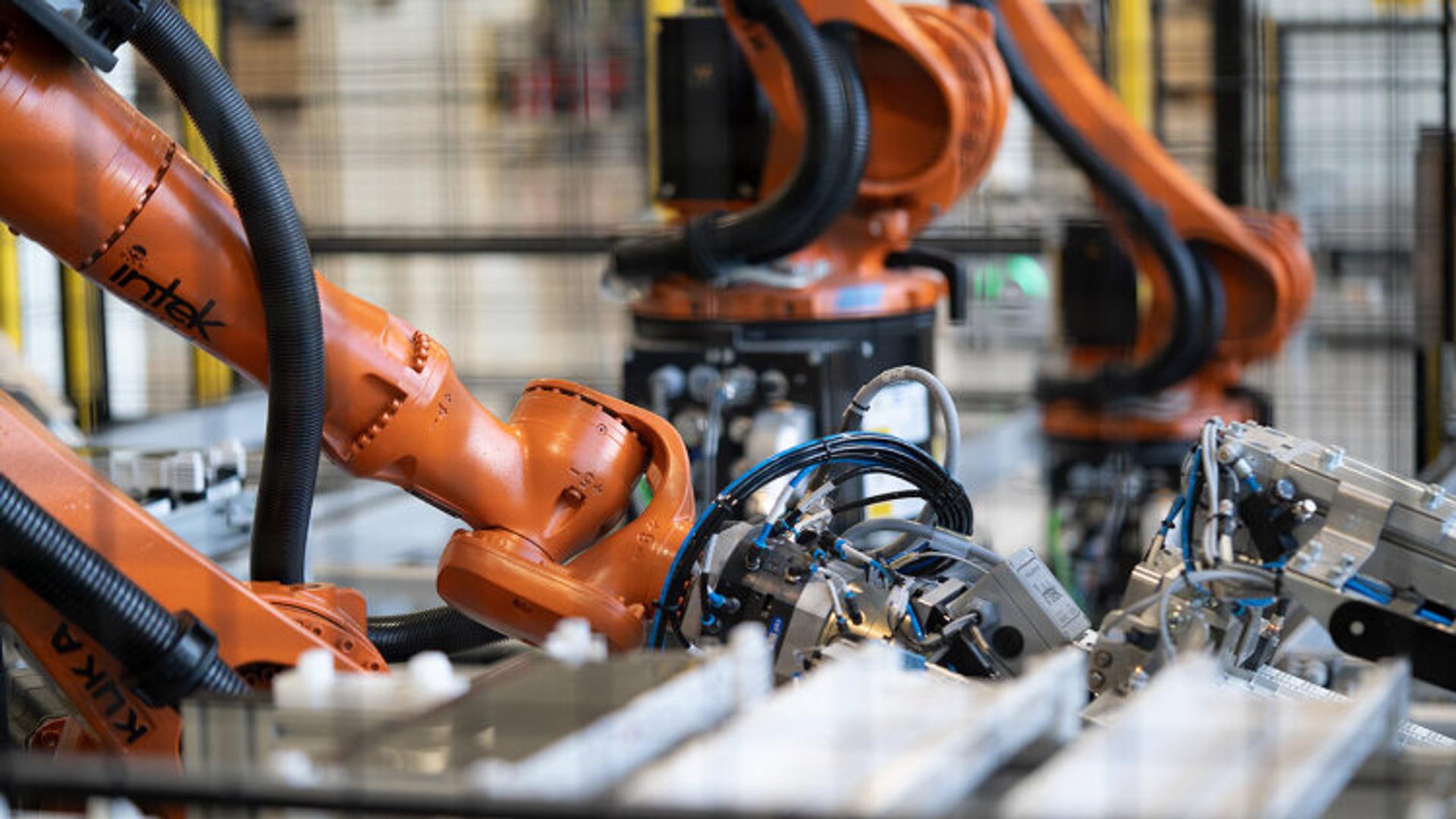

“Battery cell production – the motor of the industry – gained momentum in 2021,” says Lars Petter Maltby, CTO of the Eyde Cluster and Founder of Battery Norway, an industrial collaboration on the battery ecosystem.

“We have seen more hiring and capital investment, and two clean battery cell producers, FREYR Battery and Morrow Batteries, are ramping up their first pilot lines. It’s an exciting time.”

Exciting, indeed. Here are a few highlights from 2021: FREYR Battery and Glencore International, a global commodity company, signed a contract for the supply of partially recycled cobalt, while Norwegian industry heavyweight Elkem established Vianode as a subsidiary to produce sustainable battery materials.

In addition, Beyonder, a producer of eco-friendly batteries from sawdust, received a major climate award, and the Minister of Trade and Industry laid the cornerstone of the Morrow Research Centre, which will develop and commercialise new battery technology. But the battery industry is much more than cell manufacturing.

Expanding beyond battery cells

In 2021, progress on battery recycling accelerated, as the EU moved closer to final adoption of its revised battery directive. The new regulations will require greater use of recycled materials and better end-of-life management.

“Norway is forward leaning in recycling of EV batteries. This means we are well positioned to meet the new requirements. HydroVolt is set to open its large battery recycling plant here, and battery manufacturers already use recycled material in their production. We are also seeing the first wave of end-of-life EV batteries,” says Nora Rosenberg Grobæk, former Head of Batteries at Invest in Norway, the official investment promotion agency of Norway.

In stationary battery storage, Norway added an exciting new player, Evyon. The startup repurposes second-life EV batteries into green battery systems for energy storage in homes and businesses. Another young company, ECO STOR, signed a contract for delivery of a large ESS to the German town of Eisenbach and announced an MoU with Nissan on EV battery reuse for energy storage projects.

Sailing towards a greener maritime industry

Since before the Viking Era, Norway has been a major seafaring nation. While all eyes have been on Norway’s high EV use, the Norwegian maritime industry has been sailing ahead with its own energy transition.

“In 2021, we’ve seen lots of activity on the maritime side, where Norway is leading the world in the electrification of ferries and leisure boats.”

Nora Rosenberg Grobæk

Head of Battery Technology, Invest in Norway

Corvus Energy, a pioneer in green energy storage for the maritime sector, announced a major milestone: its 500th project order, this time for zero-emission harbour tugs. Corvus also supplied the energy storage system for the MF Hydra, the world’s first hydrogen-powered ferry.

In other news: construction began on the world’s first fully electric, zero-emission fast ferry at the Fjellstrand shipyard, and Evoy, a leader in the electric boat market, launched the next generation of its electric motor system that makes sustainable boating even more appealing.

“As the technology improves, leisure boat owners are more open to sustainable options. We’re also seeing new business models, such as the pool of electric boats for hire offered by Kruser, a green startup. It’s interesting to see how we as consumers are adapting to a new world,” says Grobæk.

Going public on the New York Stock Exchange

Hydro, the international aluminium and energy company based in Norway, has an ambition for further growth within the battery industry.

“We are aiming to build a sustainable battery business in Norway and Europe, investing up to NOK 3 billion until 2025. As an active industrial owner, we use our core capabilities to create value in the companies we establish and invest in. We see that there is a lot of transferrable competence between industries. For example, we use our aluminium recycling competence to improve battery recycling in our JV HydroVolt.”

Elise Must

Head of Strategy and Sustainability in Batteries, Hydro

Funding from abroad flowed abundantly to Norway as well. “Despite Covid, foreign investors have shown great interest in the battery value chain, and they appreciate the competitive advantages Norway has to offer,” says Grobæk.

But perhaps the biggest headlines came from FREYR Battery. On 8 July 2021, the company was listed on the New York Stock Exchange. FREYR is expected to receive roughly USD 850 million in equity proceeds, enabling the company to accelerate the development of up to 43 GWh of clean battery cell manufacturing in Norway by 2025. On 16 December 2021, FREYR announced that it had signed an offtake agreement for at least 31 GWh of battery cells with an undisclosed, leading global provider of energy storage systems.

Drawing on Norway’s culture of cooperation

Norwegians have collaboration in their blood. Coming from a small, historically isolated country, they understand the adage “there is strength in numbers”.

“On a national level, we’re seeing increasing cooperation within the battery industry. More industry players, even competitors, are collaborating, and more industrial clusters are forming,” says Grobæk.

This is equally true for cooperation among Nordic neighbours. “A strong Nordic value chain is great for all three countries. By cooperating with our Nordic friends, we can ensure we deliver on sustainability,” she adds.

Maltby agrees. “We want to strengthen all the Nordic partners. Finland has the raw materials, Norway has green electricity and a mature process industry, and Sweden has a strong industrial base. By coming together, we can make an impact on the European market,” he says.

An excellent example of Nordic cooperation is Hydrovolt, originally an EV recycling joint venture between Norway's industry giant Hydro and the now-defunct Swedish battery manufacturer Northvolt. Through recycling EV batteries, Hydrovolt recovers copper, plastics, aluminium, and “black mass” containing valuable metals such as nickel, manganese, cobalt, graphite and lithium. Hydrovolt is wholly owned by Hydro as of January 2025.

Joining forces on battery competence

As Norway quickly develops its clean battery industry, more highly skilled workers will be needed. “A key challenge in Norway is skills and skills development. This takes time, and we are lagging behind. Fortunately, I see competence-building initiatives on the horizon,” says Must.

One such initiative is the BattKOMP project, out of which a key development has arisen: an agreement among Norway’s universities and university colleges to create new study programmes, from bachelor’s through PhD, in the battery field.

“The idea is to bridge the gap, to create a national initiative to build battery competence. The Norwegian battery industry will require 10 000 highly skilled people in a few years. We won’t be successful if we don’t have the people.”

Lars Petter Maltby

CTO, Eyde Cluster

To fill the gap in the meantime, Norwegian companies increased their international hiring in 2021, recruiting experts from China, Germany, Japan, South Korea and the US.

Winning the game through sustainability

In the end, sustainability will win the long game.

The Norwegian Government has long recognised this, enacting policies to accelerate the transition to green energy. “The new labour-oriented government, which formed in 2021, has been particularly vocal in its support for a sustainable battery industry,” says Grobæk.

Companies understand this as well.

“Both in Europe and internationally, we are increasingly seeing that customers have sustainability at the top of their agenda. In our experience, companies set stricter social and environmental requirements for potential suppliers than regulators do. In short, if you are not sustainable, you are not competitive,” concludes Must.